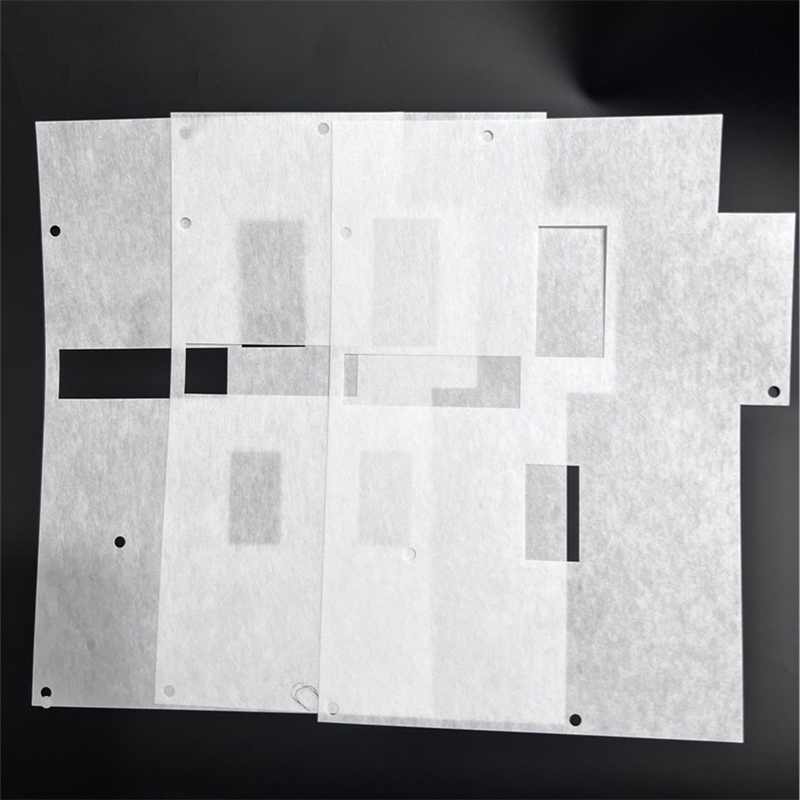

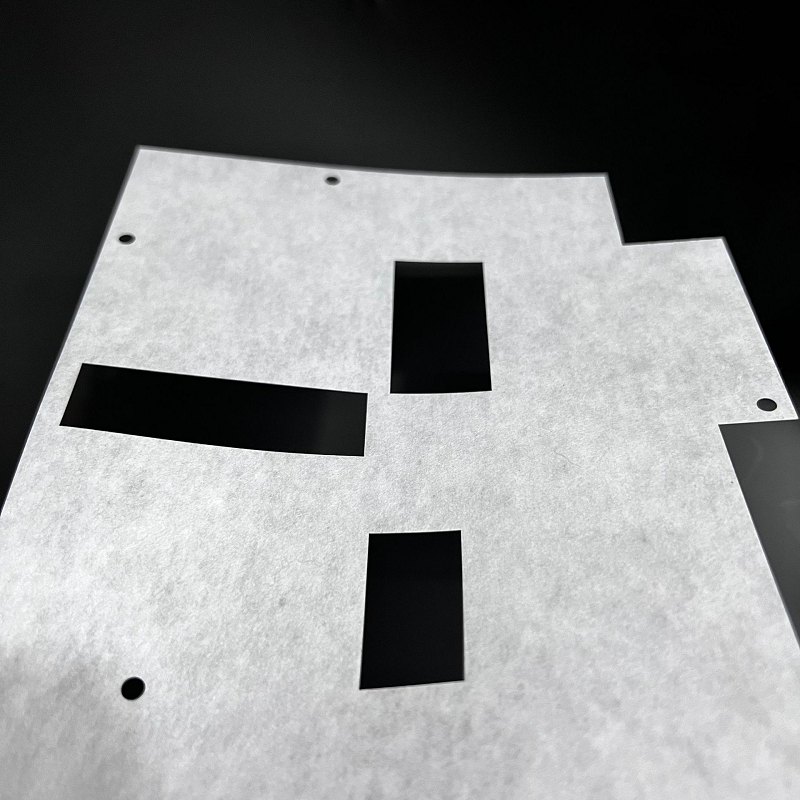

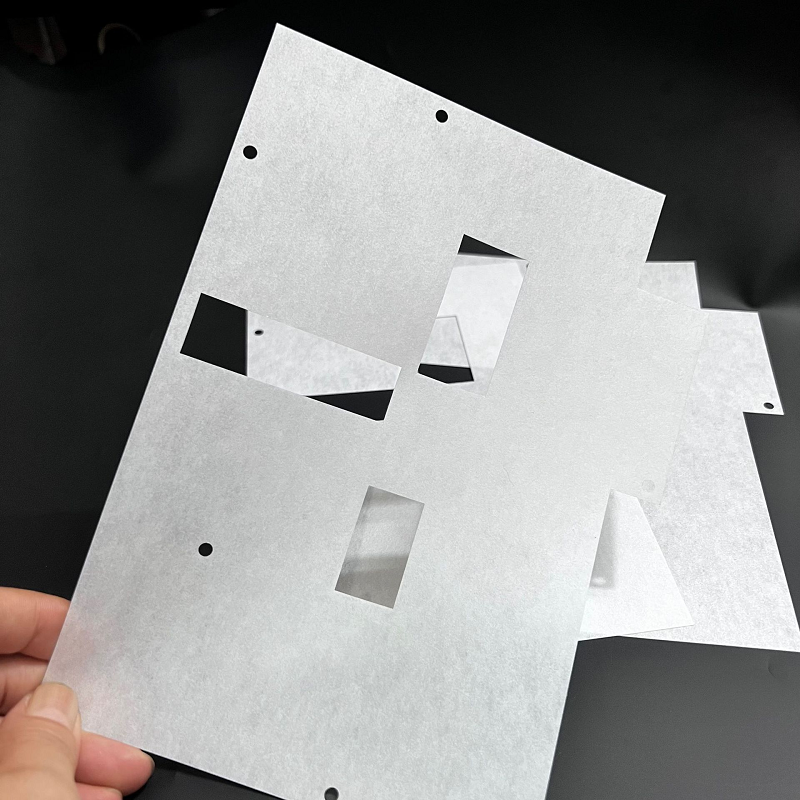

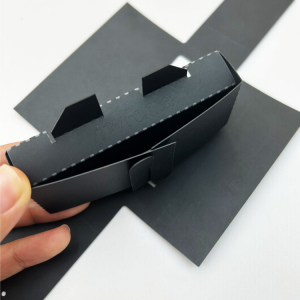

Customized Die Cutting DMD Composite Insulating paper For Motor Winding

1. Super dielectric property

2. Reliable heat resistance

3. High mechanical strength

4. Good impregnating performance

| Properties | Units | Values | ||||||||

| Nominal thickness | mm | 0.15 | 0.17 | 0.2 | 0.23 | 0.25 | 0.3 | 0.35 | ||

| Thickness tolerance | mm | ±0.02 | ±0.03 | ±0.04 | ||||||

| Grammage and tolerance | g/m2 | 180±25 | 210±30 | 240±30 | 260±35 | 300±40 | 350±50 | 430±50 | ||

| Tensile strength |

MD | No bending | N/10mm | ≥80 | ≥120 | ≥140 | ≥180 | ≥190 | ≥270 | ≥320 |

| After bending | ≥80 | ≥105 | ≥120 | ≥150 | ≥170 | ≥200 | ≥300 | |||

| TD | No bending | ≥80 | ≥105 | ≥120 | ≥150 | ≥170 | ≥200 | ≥300 | ||

| After bending | ≥70 | ≥90 | ≥100 | ≥120 | ≥130 | ≥150 | ≥200 | |||

| Elongation | MD | No bending | % | ≥15 | / | |||||

| After bending | ≥10 | ≥5 | ||||||||

| TD | No bending | ≥20 | / | |||||||

| After bending | ≥10 | ≥5 | ||||||||

| Breakdown Voltage No bending | KV | ≥6 | ≥7 | ≥9 | ≥10 | ≥12 | ≥15 | ≥18 | ||

| Bonding property at room temp. | / | No delamination | ||||||||

| Bonding property at 180±2℃ 10min | No delamination, no bubble, no adhesive flow | |||||||||

| Temp.index of heat-resistance in a long term (TI) | / | ≥155 | ||||||||

| The quality warranty period | / | Twelve months | ||||||||

It is used for motors, generators and electric appliances in the slot insulation, liner insulation and turn to turn insulation.

DMD is typically used on low and medium voltage electric machines. Specific applications include:

—Slot liner for electric motors.

—Phase insulation.

—Interlayer insulation material for transformers

Write your message here and send it to us