OUR CAPABILITIES

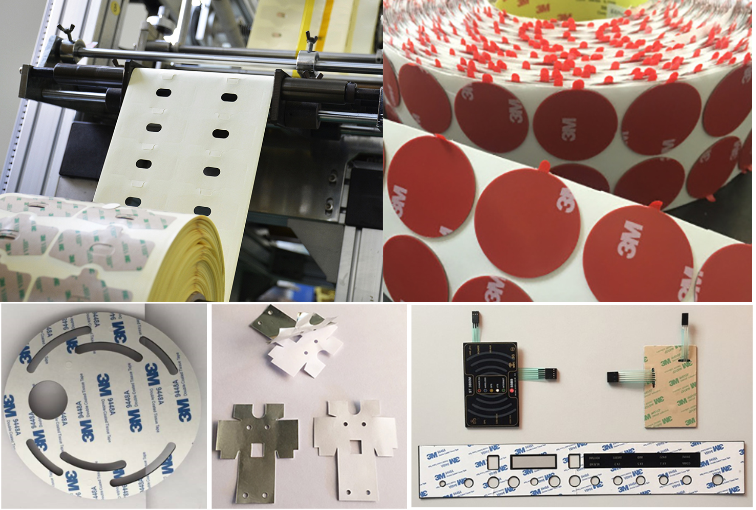

Die Cutting

Die cutting is a critical process that allows for the precise conversion of materials into specific shapes and sizes. Utilizing advanced die-cutting equipment, we can handle a wide range of materials, from tapes and films to foams and fabrics.

Our die-cutting capabilities include rotary and flatbed cutting, enabling us to produce everything from simple gaskets to complex, multi-layered components. This process ensures that every piece is cut with consistent accuracy, making it ideal for high-volume production runs as well as custom, one-off projects. Whether you need intricate patterns or standard shapes, our die-cutting services deliver precision, efficiency, and reliability.

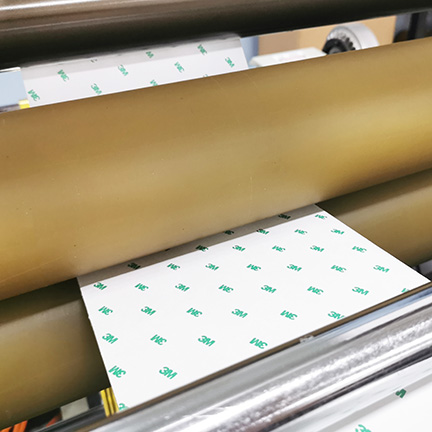

Laminating

Laminating is an essential process that enhances the functionality and durability of materials by bonding them with protective layers.

Our laminating services are designed to meet a variety of industrial needs, whether it's adding a barrier against moisture, increasing tensile strength, or improving surface aesthetics. We work with a wide range of substrates, including films, foams, and specialty tapes, to create multi-layered constructions that meet your specific requirements. Our laminating process is meticulously controlled to ensure uniformity and adhesion, resulting in a finished product that performs under even the most demanding conditions. From improving product longevity to enhancing visual appeal, our laminating solutions are tailored to elevate your materials to the next level.

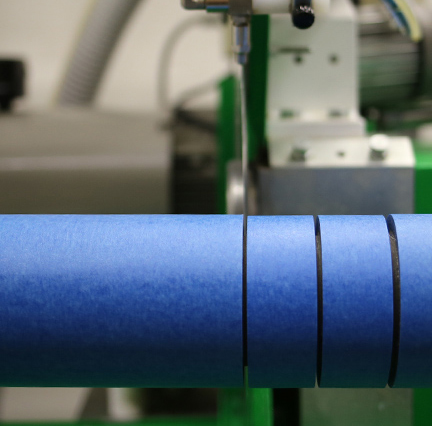

Slitting

Slitting is a crucial process for converting wide rolls of material into narrower, more manageable widths.

Our slitting services are designed to accommodate a variety of materials, including films, foils, papers, and tapes, ensuring that they are cut to your exact specifications. With precision slitting equipment, we can achieve clean, straight cuts with tight tolerances, ensuring that the material is perfectly sized for your application. Our slitting capabilities also include the ability to handle both large and small rolls, making us a versatile partner for all your material conversion needs. Whether you require custom widths for specific applications or need bulk material prepared for further processing, our slitting services ensure efficiency, quality, and precision at every step.

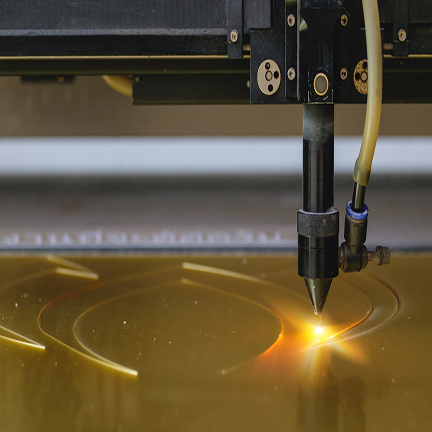

Laser Cutting

Laser cutting offers unparalleled precision and versatility, making it an ideal solution for creating complex designs and intricate patterns.

Our state-of-the-art laser cutting technology allows us to work with a diverse range of materials, including metals, plastics, and composites, delivering clean, precise cuts with minimal waste. The non-contact nature of laser cutting ensures that the material's integrity is maintained, even when working with delicate or sensitive substrates. This process is highly efficient, enabling rapid prototyping and short lead times, while also accommodating large-scale production needs. Whether you're looking to produce detailed components or need a reliable method for cutting complex shapes, our laser cutting services provide the accuracy and consistency required for superior results.